The booming cannabis industry demands innovation, precision, and efficiency. From cultivation to processing, the right cannabis equipment plays a vital role in achieving high-quality yields and compliant operations. Whether you’re a grower, extractor, or processor, understanding the scope of 420 equipment is key to enhancing productivity and ensuring consistent results.

In this guide, we’ll break down the must-have cannabis equipment across different stages of the cannabis lifecycle, explain their functions, and help you make informed decisions for your operations.

Understanding Cannabis Equipment and Its Role in the Industry

The term cannabis equipment refers to a wide range of tools and machinery used in the cultivation, processing, testing, and packaging of cannabis products. With growing legalization and demand for premium products, high-performance 420 equipment has become essential for both small-scale and large-scale operators.

Cannabis operations typically involve several stages:

- Cultivation (indoor or outdoor)

- Harvesting and trimming

- Drying and curing

- Extraction and processing

- Packaging and labeling

- Compliance testing

Each of these stages benefits from specialized cannabis equipment designed to increase efficiency, minimize waste, and maintain product integrity.

Types of Cannabis Equipment

From indoor grow rooms to large-scale processing facilities, here are the essential equipment categories:

Cultivation Equipment

Successful cannabis cultivation depends on precise environmental control. Some of the must-have tools include:

- Grow lights (LED or HID)

- HVAC systems

- Humidity and temperature controllers

- Hydroponic systems or soil grow setups

- Irrigation and nutrient delivery systems

These tools ensure optimal growing conditions, higher cannabinoid production, and improved terpene profiles.

Harvesting Equipment

Once your plants mature, the harvesting phase begins. Tools you might need include:

- Trimmers (manual or automatic)

- Drying racks

- Dehumidifiers

- Scissors and gloves for manual trimming

- Storage bins for plant material

Automated trimmers are especially useful for commercial growers looking to save time and reduce labor costs.

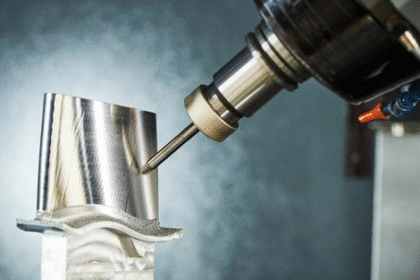

Processing and Extraction Equipment

Processing cannabis into oils, tinctures, edibles, or concentrates requires specialized equipment. Popular options include:

- Rosin presses

- Closed-loop extraction systems

- Distillation units

- Winterization and filtration tools

Depending on your end product, your setup may be simple or require an entire lab environment.

Essential Cultivation Equipment for Cannabis Growers

Whether you’re growing at home or running a commercial facility, cannabis cultivation begins with the right environment and tools.

Lighting and Climate Control

Indoor cannabis grows rely heavily on proper lighting. Options include:

- LED grow lights

- HPS (High-Pressure Sodium) lights

- CMH (Ceramic Metal Halide) lamps

Climate control systems ensure optimal temperature, humidity, and airflow. These include:

- HVAC systems

- Dehumidifiers

- Air filtration systems

Grow Tents and Hydroponic Systems

Grow tents are ideal for personal or indoor grows, offering a controlled environment. Hydroponic setups provide soilless cultivation, often paired with nutrient delivery systems for maximum efficiency.

Nutrient Dispensers and Irrigation

Automated irrigation systems, drip lines, and nutrient dosing machines streamline watering schedules and prevent human error, particularly in large-scale grow operations.

Post-Harvest and Processing Cannabis Equipment

After cultivation, cannabis must be trimmed, dried, and prepared for extraction or retail.

Trimming Machines

Manual trimming can be time-consuming. Automated trimmers speed up the process while preserving trichomes and reducing labor costs.

Drying and Curing Chambers

Drying rooms or chamber systems ensure slow, even drying while maintaining the cannabinoid profile. Humidity and temperature controls are crucial during curing.

Extraction Equipment

Cannabis extraction is a complex process that converts raw flower into oils, concentrates, and other forms. Common extraction types include:

- CO₂ extraction

- Hydrocarbon (butane/propane) extraction

- Ethanol extraction

- Rosin presses for solventless extraction

Packaging, Testing, and Compliance Tools

Packaging Machines

Once processed, cannabis products require compliant and attractive packaging. Equipment includes:

- Weighing and filling machines

- Heat sealers

- Label applicators

Compliance and Testing Equipment

Lab equipment ensures product purity, potency, and compliance. While third-party labs often handle testing, in-house systems are gaining traction for quality control.

Conclusion

The cannabis industry’s rapid expansion has led to a diverse and advanced ecosystem of cannabis equipment designed to support every stage of production. From precision lighting to cutting-edge extraction systems, 420 equipment offers scalable solutions for cultivators, processors, and distributors alike. Investing in the right tools can boost yields, improve efficiency, and ensure consistent quality across your operation.

FAQs

Q1: What is the most important cannabis equipment for beginners?

A1: For beginners, basic cultivation gear such as LED lights, grow tents, and climate control systems are essential to ensure a successful harvest.

Q2: What are the different types of cannabis extraction equipment?

A2: The most common types include CO₂, ethanol, hydrocarbon, and solventless extraction systems. Each has its pros and cons depending on budget and product goals.

Q3: Is cannabis equipment regulated?

A3: Yes. Especially in extraction and packaging, equipment must meet safety and compliance standards based on regional cannabis laws.

Q4: Can I automate my cannabis grow operation?

A4: Absolutely. From irrigation systems to automated trimmers and nutrient dosing machines, many processes can be streamlined using 420 equipment.

Q5: Where can I find quality cannabis equipment?

A5: For a wide selection of reliable and advanced cannabis equipment, visit 420 Equipment.