In today’s creative world, embroidery digitizing stands at the intersection of artistry and technology. What was once a fully manual craft—hand-stitching logos, monograms, and motifs—has evolved into a highly precise, software-driven process. With modern digitizing tools and professional expertise, any artwork can be transformed into a flawless embroidered masterpiece.

Embroidery digitizing is more than just converting an image into stitches. It involves understanding fabric behavior, machine compatibility, and stitch types to ensure durability and accuracy. For brands, digitizing ensures consistent logo reproduction across products; for individuals, it transforms ideas into tangible embroidered designs that last.

Understanding the Process of Embroidery Digitizing

The digitizing process transforms a visual design into a set of commands for an embroidery machine. Each color, shape, and line is translated into a unique stitch type and direction, ensuring the design appears exactly as intended when embroidered.

1. Artwork Preparation

The process begins with a clear, high-resolution image. A digitizer refines this artwork, simplifying details and determining which parts will be embroidered with different stitch styles.

2. Importing into Digitizing Software

Programs like Wilcom, Hatch, or Embrilliance allow professionals to outline design areas, select stitch types, and map colors. The software serves as a digital canvas, turning images into stitch-based blueprints.

3. Stitch Planning

The most critical phase involves selecting appropriate stitches. Satin stitches are ideal for letters and borders, fill stitches cover large areas, and run stitches outline or connect details. Each decision affects how the final embroidery looks and performs.

4. Underlay and Density Adjustments

Before visible stitches are applied, underlay stitches provide a foundation. This stabilizes fabric movement and adds volume. The digitizer also fine-tunes stitch density to avoid puckering and ensure balance.

5. Test Run and Revision

Once the design is digitized, it’s tested on the actual material. The sample run helps identify imperfections or density issues that need correction before production begins.

Why Quality Digitizing Matters

Embroidery quality begins long before the machine starts stitching. A well-digitized design can run smoothly, reduce thread breaks, and produce crisp results—while poor digitizing can ruin fabric and waste time.

For Businesses

Companies rely on embroidery for branding uniforms, caps, and promotional items. Accurate digitizing ensures every logo matches brand colors, placement, and proportions perfectly.

For Hobbyists and Designers

Home embroiderers and small creators use digitizing to personalize gifts or start custom apparel lines. With proper digitizing, even basic machines can produce professional-quality results.

Core Elements of Perfect Digitizing

Creating flawless embroidery involves balancing art and engineering. Every design depends on these critical elements:

-

Stitch Type Selection: Matching stitch type with design shape ensures smooth outlines and proper texture.

-

Pathing: Optimized stitch order minimizes trims, jumps, and thread changes.

-

Density Control: Too many stitches can cause stiffness; too few make the design look incomplete.

-

Underlay Technique: Proper underlay supports the top stitches and prevents fabric distortion.

-

Pull Compensation: Adjustments made to counter fabric stretch, keeping proportions intact.

A skilled digitizer combines these elements intuitively, transforming simple artwork into durable embroidered art.

Popular File Formats for Embroidery Digitizing

Different machines require specific file formats. Choosing the correct one is vital for error-free operation.

| File Type | Machine Brand | Notes |

|---|---|---|

| DST | Tajima | Most commonly used worldwide |

| PES | Brother / Babylock | Ideal for home embroidery |

| EXP | Melco / Bernina | Supports large commercial designs |

| JEF | Janome | Compatible with domestic machines |

| HUS | Husqvarna | Good for layered stitch designs |

Always confirm your machine’s format before starting production. Using the wrong file can result in color mismatch or thread path errors.

Software Used for Embroidery Digitizing

Digitizing software determines the precision and flexibility of design creation. Here are a few leading programs used by professionals:

-

Wilcom Embroidery Studio: Offers advanced stitch simulation and layering tools.

-

Hatch Embroidery: Designed for small businesses and custom creators.

-

Embird: Known for efficient color management and scalable features.

-

Pulse DGML: High-end software for large production houses.

-

Brother PE-Design: Perfect for home embroiderers who want control with simplicity.

These platforms not only convert artwork but also simulate how the design will stitch out, helping users predict real-world results.

Industries That Depend on Embroidery Digitizing

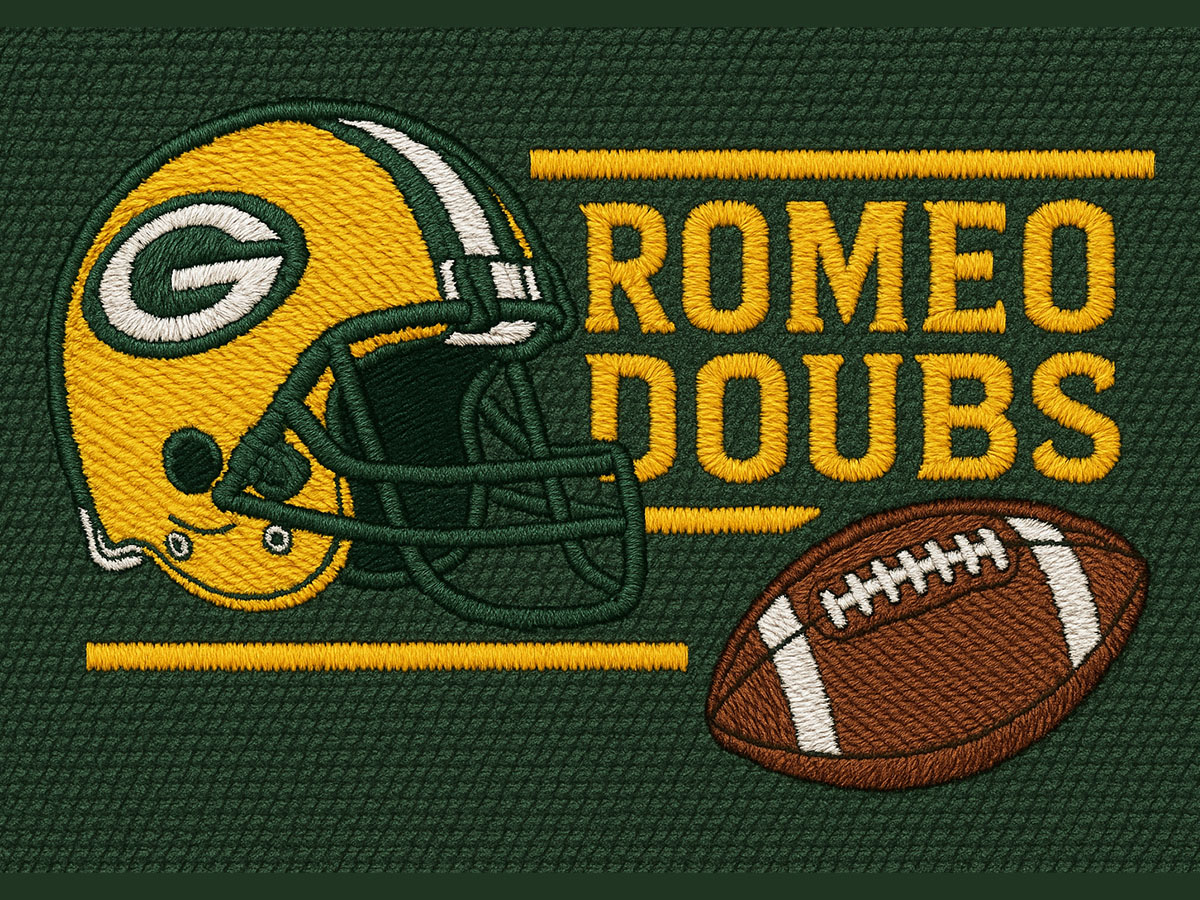

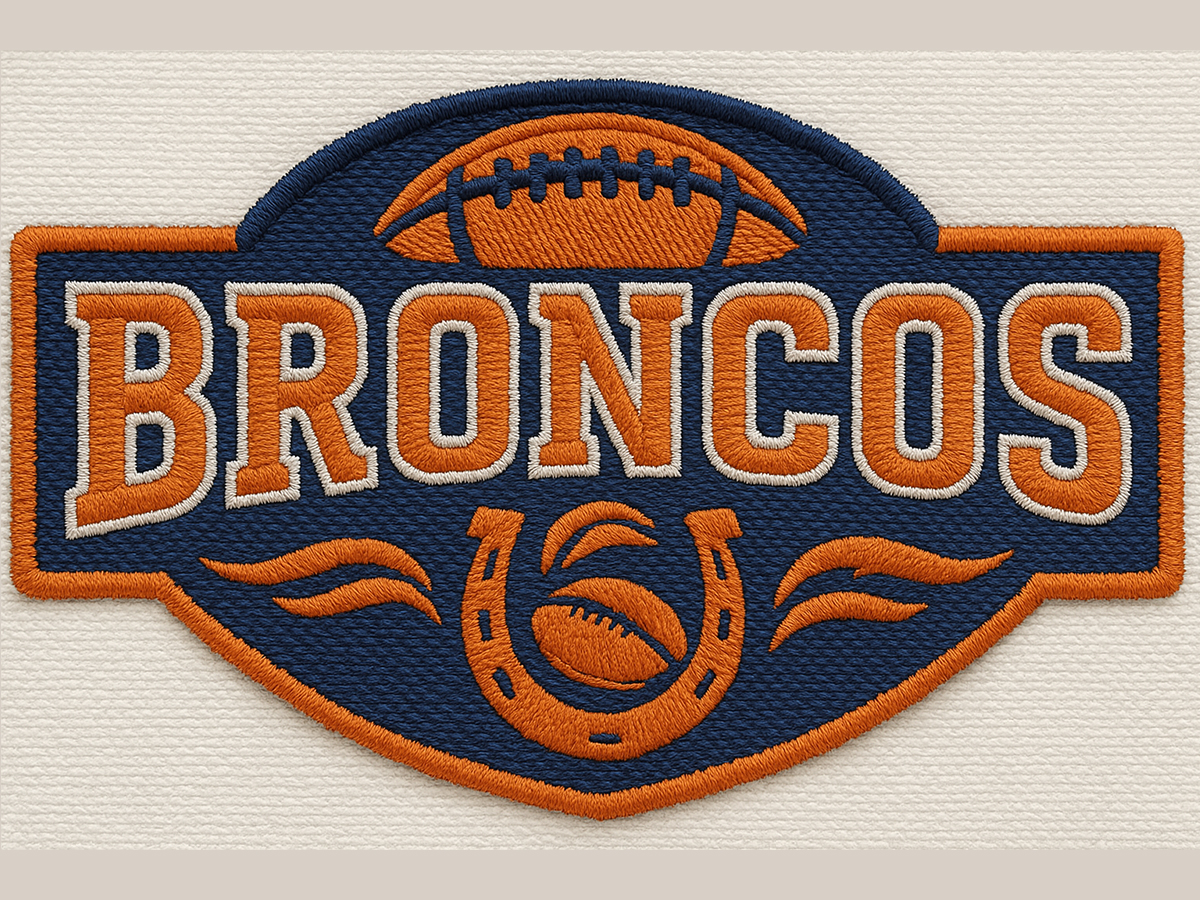

Embroidery digitizing supports countless industries across fashion, sports, and corporate sectors.

-

Corporate Apparel: Company logos embroidered on uniforms, shirts, and caps.

-

Sports Teams: Jerseys and team gear showcasing mascots and player numbers.

-

Fashion Brands: Decorative stitching on jeans, jackets, and handbags.

-

Military & Government: Patches for identification and pride.

-

Gift and Souvenir Makers: Personalized items for weddings, birthdays, and holidays.

Each sector values the precision and quality that only expert digitizing can deliver.

Advantages of Professional Digitizing Services

Choosing a professional digitizing service ensures your designs are both visually appealing and technically flawless.

-

Accuracy and Consistency: Professional files reproduce designs identically every time.

-

Fabric Compatibility: Experts adjust stitch styles for cotton, polyester, leather, or denim.

-

Fewer Production Errors: Optimized stitch paths prevent breaks and reduce downtime.

-

Brand Reliability: Maintains brand integrity with precise color mapping.

-

Scalability: Designs can be resized for multiple products without distortion.

Investing in expert digitizing saves time and delivers embroidery that reflects quality craftsmanship.

Common Challenges in Embroidery Digitizing

Even skilled digitizers face challenges that require experience to overcome:

-

Small Lettering: Hard to stitch clearly under 0.25 inches; may need density reduction.

-

Fabric Stretching: Requires extra underlay or pull compensation.

-

Color Blending: Gradient effects need careful layering to avoid harsh transitions.

-

Thread Breakage: Caused by dense stitches or incorrect sequencing.

Professionals solve these problems by testing, adjusting, and ensuring the final output runs seamlessly on machines.

Example: Business Logo Digitizing on Polo Shirts

Imagine a corporate logo featuring fine text, a circular border, and three colors. The digitizer breaks the design into layers—starting with the base fill, followed by underlay, then satin outlines. Adjustments are made for shirt texture (usually pique cotton), ensuring no puckering. After the sample test, the final design maintains clarity and alignment, even after multiple washes.

This level of precision showcases why digitizing is an art form that merges creativity with engineering.

Future Trends in Embroidery Digitizing

As technology advances, digitizing continues to evolve. AI-driven tools are now assisting in auto-pathing, color prediction, and density optimization. Cloud-based systems allow remote teams to collaborate in real-time. 3D puff embroidery, gradient stitch blending, and metallic thread digitizing are emerging trends reshaping the industry.

Sustainability is another focus. Efficient stitch pathing reduces thread waste, while eco-friendly threads contribute to greener production processes.

Benefits of High-Quality Embroidery Digitizing

High-quality digitizing creates embroidery that looks professional, feels smooth, and lasts longer. Some key benefits include:

-

Enhanced Visual Appeal: Smooth edges and uniform stitching.

-

Durability: Proper density ensures designs withstand wear and washing.

-

Efficiency: Reduced downtime from thread breaks or trimming.

-

Cost Savings: Optimized files require fewer adjustments during production.

-

Brand Recognition: Consistent results strengthen customer trust.

With skilled digitizing, embroidery becomes not just decoration—but a statement of quality.

Best Practices for Perfect Embroidery Digitizing

-

Start with High-Quality Artwork: Clear, vector-based images produce better results.

-

Test on Actual Fabric: Always do a sample run before bulk production.

-

Use Correct Thread Tension: Prevents loops or uneven stitching.

-

Mind the Scale: Resize carefully to maintain stitch integrity.

-

Focus on Simplicity: Complex designs may not always translate well to embroidery.

A methodical approach ensures that every stitch contributes to a perfect final outcome.

FAQs About Embroidery Digitizing

1. What does a digitizer do?

A digitizer converts artwork into a format that embroidery machines can understand, determining stitch type, order, and density.

2. Can any image be digitized?

Yes, but overly detailed or gradient-heavy images may need simplification to translate well into stitches.

3. How much does professional digitizing cost?

Prices vary depending on complexity, stitch count, and turnaround time. Simple designs cost less than detailed logos.

4. How do I know if my design is well digitized?

A well-digitized file runs smoothly, has no thread breaks, and visually matches the original artwork when embroidered.

5. Which industries use digitizing the most?

Corporate branding, sportswear, fashion, and custom patch manufacturers rely heavily on digitizing services.

Conclusion

Embroidery digitizing transforms creative ideas into precise, long-lasting embroidery through skill, software, and attention to detail. Whether for branding, fashion, or personal use, it ensures every stitch is placed perfectly. From artwork preparation to final execution, this process combines creativity with technology to produce embroidery that stands out for its quality and consistency.

True mastery in embroidery digitizing lies in understanding both the art and science of stitching—a skill that continues to define excellence in modern embroidery worldwide.